Types and Applications of Wire Mesh Inserts

Wire mesh inserts offer a unique blend of functionality and aesthetics for cabinet doors, providing ventilation, visual interest, and a modern design element. Their application extends beyond purely decorative purposes, impacting both the practicality and style of various cabinetry styles. The choice of material and mesh pattern significantly influences the overall look and durability of the finished product.

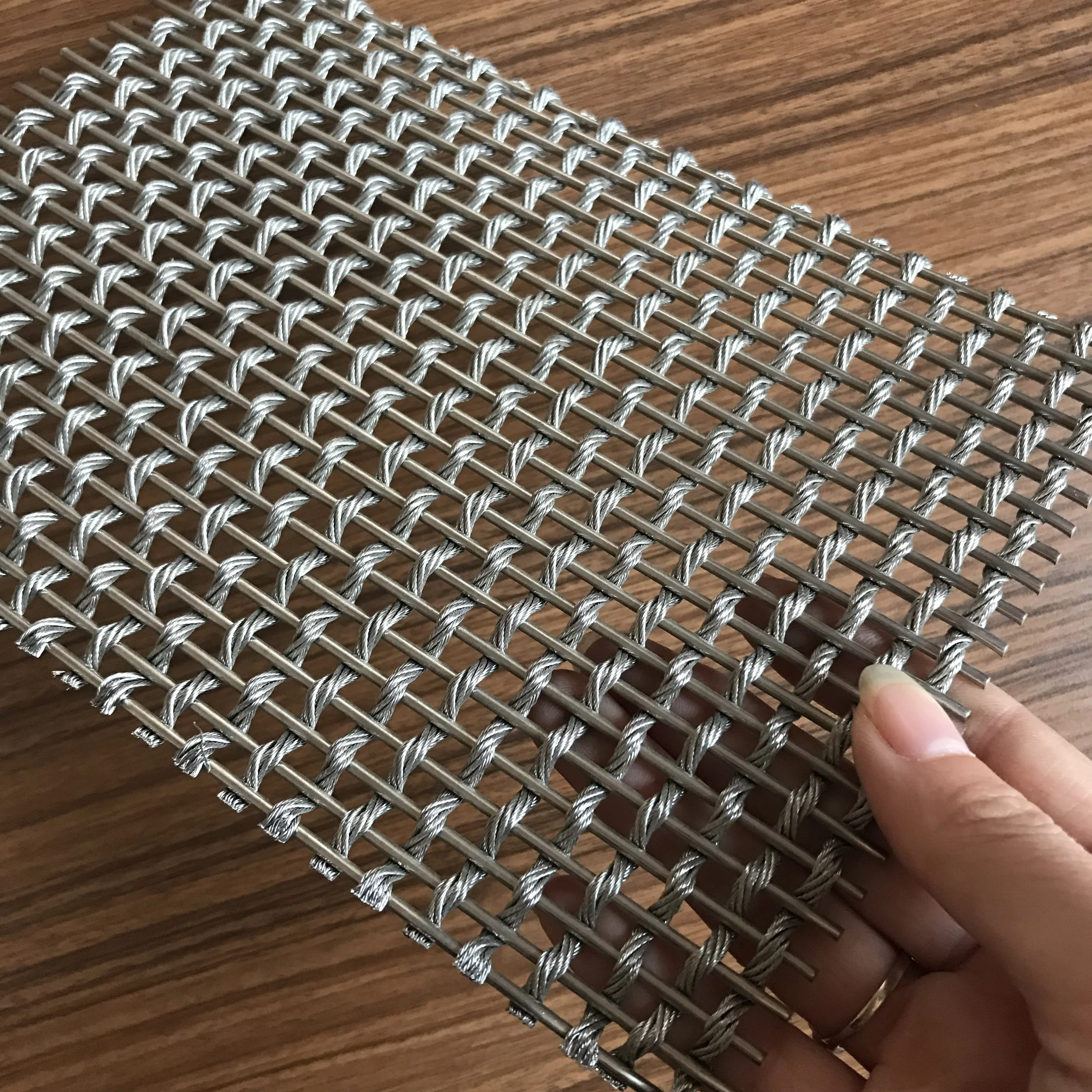

Materials Used in Wire Mesh Inserts

Several materials are commonly used for creating wire mesh inserts, each possessing distinct advantages and disadvantages. Steel wire mesh is a robust and economical option, offering good strength and durability. However, it is susceptible to rust and requires a protective finish, such as powder coating, to prevent corrosion. Aluminum wire mesh is lighter and more resistant to corrosion than steel, making it a suitable choice for humid environments like bathrooms. Its inherent lightness, however, might mean it’s less sturdy than steel for heavier doors. Stainless steel wire mesh combines the strength of steel with excellent corrosion resistance, making it a premium, long-lasting choice. While more expensive than steel or aluminum, its longevity justifies the cost for high-end applications.

Applications of Wire Mesh Inserts in Different Cabinet Styles

Wire mesh inserts find applications across a wide range of cabinetry styles. In kitchens, they can be used in pantry doors to allow for ventilation and visibility of stored items. Bathroom vanities benefit from the ventilation provided by mesh inserts, preventing moisture buildup and mildew. Media centers can utilize wire mesh inserts to conceal electronics while allowing for heat dissipation, preventing overheating. In wine cellars, mesh inserts offer a stylish way to display wine bottles while ensuring proper air circulation.

Aesthetic Comparison: Wire Mesh vs. Solid Cabinet Doors

The visual impact of wire mesh inserts differs significantly from solid cabinet doors. Solid doors provide a clean, uninterrupted surface, ideal for minimalist or traditional designs. Wire mesh inserts, on the other hand, introduce a textured, often patterned element, adding visual interest and a more contemporary feel. A key difference lies in light transmission; wire mesh allows light to pass through, creating a sense of openness and potentially illuminating the cabinet’s contents. This can be particularly advantageous in darker spaces or for showcasing attractive items within the cabinet. The choice between solid and mesh doors depends on the desired aesthetic and the overall design scheme of the room.

Wire Mesh Patterns and Suitability for Cabinet Styles

| Wire Mesh Pattern | Description | Suitable Cabinet Styles | Notes |

|---|---|---|---|

| Diamond | Interlocking diamond shapes create a classic, slightly more intricate pattern. | Traditional, Transitional, Farmhouse | Provides good ventilation and visual interest. |

| Square | Simple, clean lines create a modern and minimalist look. | Modern, Contemporary, Minimalist | Offers excellent ventilation and a sleek appearance. |

| Hexagonal | Unique hexagonal shapes offer a more distinctive and sophisticated design. | Modern, Industrial, Eclectic | Provides good ventilation and a visually striking pattern. |

| Woven | A more complex pattern with interwoven wires, offering a decorative and textured appearance. | Rustic, Transitional, Farmhouse | Can be more difficult to clean, but adds significant visual depth. |

Installation and Maintenance of Wire Mesh Inserts: Wire Mesh Inserts For Cabinet Doors

Installing wire mesh inserts into your cabinet doors can significantly enhance their aesthetic appeal and functionality. This process, while seemingly straightforward, requires careful attention to detail to ensure a secure and professional finish. Proper installation prevents issues like sagging or rattling, maintaining the integrity of your cabinets for years to come.

Wire mesh inserts for cabinet doors – The installation process generally involves several key steps, and the specific techniques may vary slightly depending on the type of wire mesh and cabinet door design. However, the fundamental principles remain consistent.

Tools and Materials Required for Installation

Before starting, gather the necessary tools and materials. This typically includes the wire mesh insert itself, measuring tape, a pencil, tin snips or wire cutters (for trimming the mesh), strong adhesive (such as construction adhesive or epoxy), possibly screws and/or brackets (depending on the installation method), a level, and a putty knife for cleaning up excess adhesive. Safety glasses are also recommended to protect your eyes from any potential debris.

Step-by-Step Installation Process

- Measure and Cut: Carefully measure the interior dimensions of your cabinet door where the mesh will be installed. Transfer these measurements to the wire mesh and use tin snips or wire cutters to accurately cut the mesh to size. Ensure a snug fit, leaving minimal space for movement.

- Clean the Surface: Thoroughly clean the inside surface of the cabinet door where the mesh will adhere. Remove any dust, debris, or old adhesive residue. A clean surface ensures optimal adhesion.

- Apply Adhesive: Apply a generous but even layer of construction adhesive or epoxy to the back of the wire mesh. Follow the manufacturer’s instructions regarding application and drying time.

- Position and Secure: Carefully position the wire mesh insert inside the cabinet door, ensuring it’s level and aligned. Use weights or clamps to hold it in place while the adhesive cures. Alternatively, you can use screws or brackets, predrilling pilot holes to prevent damage to the mesh or door.

- Remove Excess Adhesive: Once the adhesive has cured (refer to the manufacturer’s instructions), carefully remove any excess adhesive that has squeezed out from the edges using a putty knife. Clean the area thoroughly.

Troubleshooting Common Installation Issues, Wire mesh inserts for cabinet doors

Several challenges can arise during installation. For instance, uneven adhesion might occur if the surface isn’t properly cleaned. To solve this, remove the mesh, clean the surface again, and reapply the adhesive. If the mesh is too large, carefully trim it with wire cutters to achieve the correct size. If the mesh sags, ensure proper support by using additional adhesive or supplemental brackets.

Regular Maintenance Schedule for Wire Mesh Inserts

Regular maintenance ensures the longevity and aesthetic appeal of your wire mesh inserts. A simple cleaning and inspection routine will prevent issues and maintain their appearance.

- Monthly Cleaning: Wipe down the mesh with a damp cloth and mild detergent. Avoid harsh chemicals that could damage the finish.

- Annual Inspection: Check for any signs of damage, rust, or loose adhesion. Tighten any loose screws or brackets and reapply adhesive if necessary.

- Repair Procedures: For minor damage, such as small dents or scratches, you might be able to repair them using a fine-grit sandpaper and touch-up paint. For more significant damage, replacement may be necessary.

Cost and Sourcing of Wire Mesh Inserts

The price of wire mesh inserts varies considerably, depending on several key factors. Understanding these factors helps you make informed decisions when budgeting for your project and choosing a supplier. Knowing where to look for these inserts is just as important as understanding the cost.

Several factors significantly impact the final cost of wire mesh inserts. Material choice is a major player; stainless steel, for instance, will be more expensive than coated steel or aluminum. The size of the insert is another crucial element; larger inserts naturally cost more due to the increased amount of material and manufacturing time involved. Finally, the intricacy of the design influences the price. Elaborate patterns or custom designs add to the manufacturing complexity and, therefore, the cost. Think of it like this: a simple rectangular insert will be cheaper than a complex, custom-shaped insert with intricate cutouts.

Factors Affecting the Cost of Wire Mesh Inserts

Material type significantly affects pricing. Stainless steel, known for its durability and resistance to corrosion, commands a higher price compared to less robust materials like coated steel or aluminum. Size also plays a critical role; larger inserts require more material and labor, leading to increased costs. Finally, design complexity directly influences the manufacturing process and, consequently, the price. A simple, geometric design is less expensive to produce than a more elaborate, custom-designed insert.

Sourcing Wire Mesh Inserts

Several avenues exist for purchasing wire mesh inserts. Online retailers offer a wide selection and often provide competitive pricing, although shipping costs need to be considered. Home improvement stores are another convenient option, providing readily available inserts, though their selection might be more limited. Specialized suppliers, often catering to industrial or commercial needs, offer a wider range of materials, sizes, and designs but might have higher minimum order quantities.

Comparison of Suppliers and Pricing

Direct comparison of pricing and features between different suppliers is difficult without specifying exact product requirements (size, material, design). However, generally, online retailers tend to offer competitive prices on standard sizes and designs, while specialized suppliers may offer better pricing on larger orders or custom designs. Home improvement stores usually offer a convenient but possibly more limited selection at a mid-range price point. For example, a basic, small aluminum insert might cost around $10-$20 from a home improvement store, while a large, custom stainless steel insert could easily cost several hundred dollars from a specialized supplier.